Enginuity colleague visits during National Manufacturing Day 2024

Date

03/10/2024

Category

News , Insights

In celebration of National Manufacturing Day, the Enginuity team visited several manufacturers across the UK, engaging with industry leaders, apprentices, and educational institutions to highlight innovation and skill development in the manufacturing sector. These visits offered valuable insights into the diversity of UK manufacturing and its commitment to future talent.

West Yorkshire Manufacturing Services

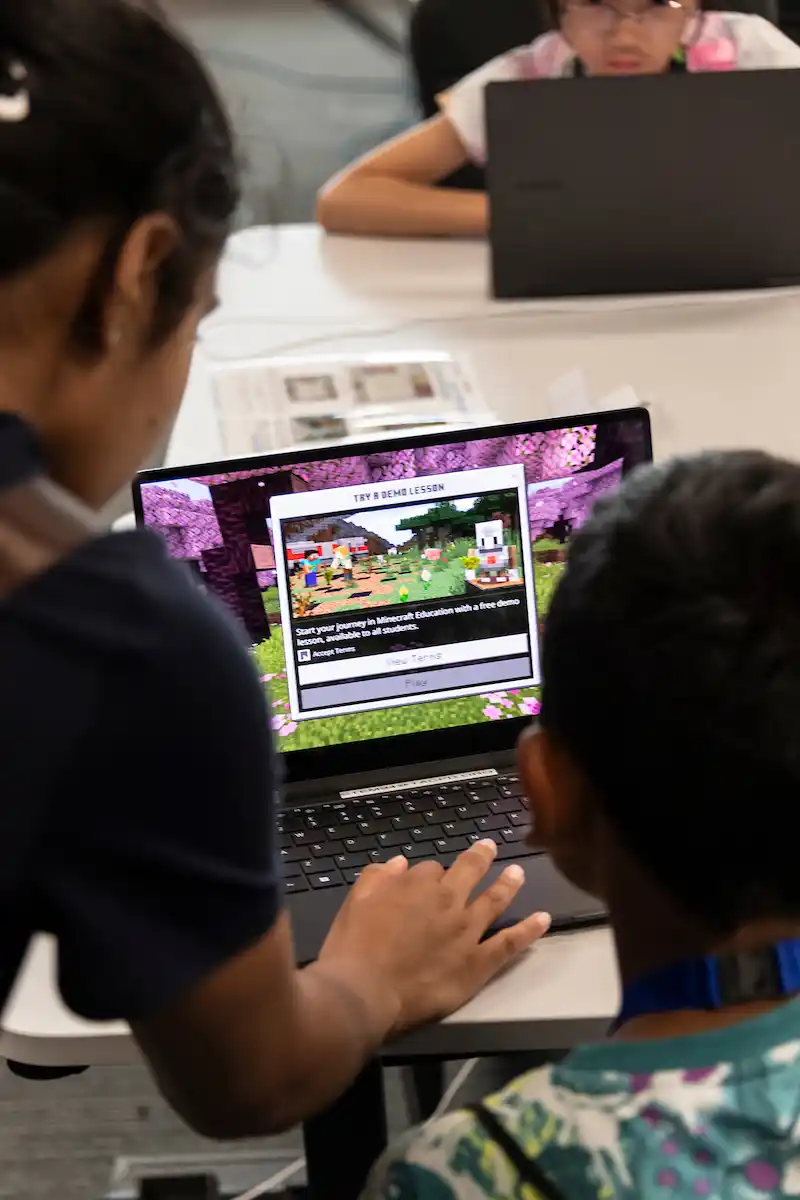

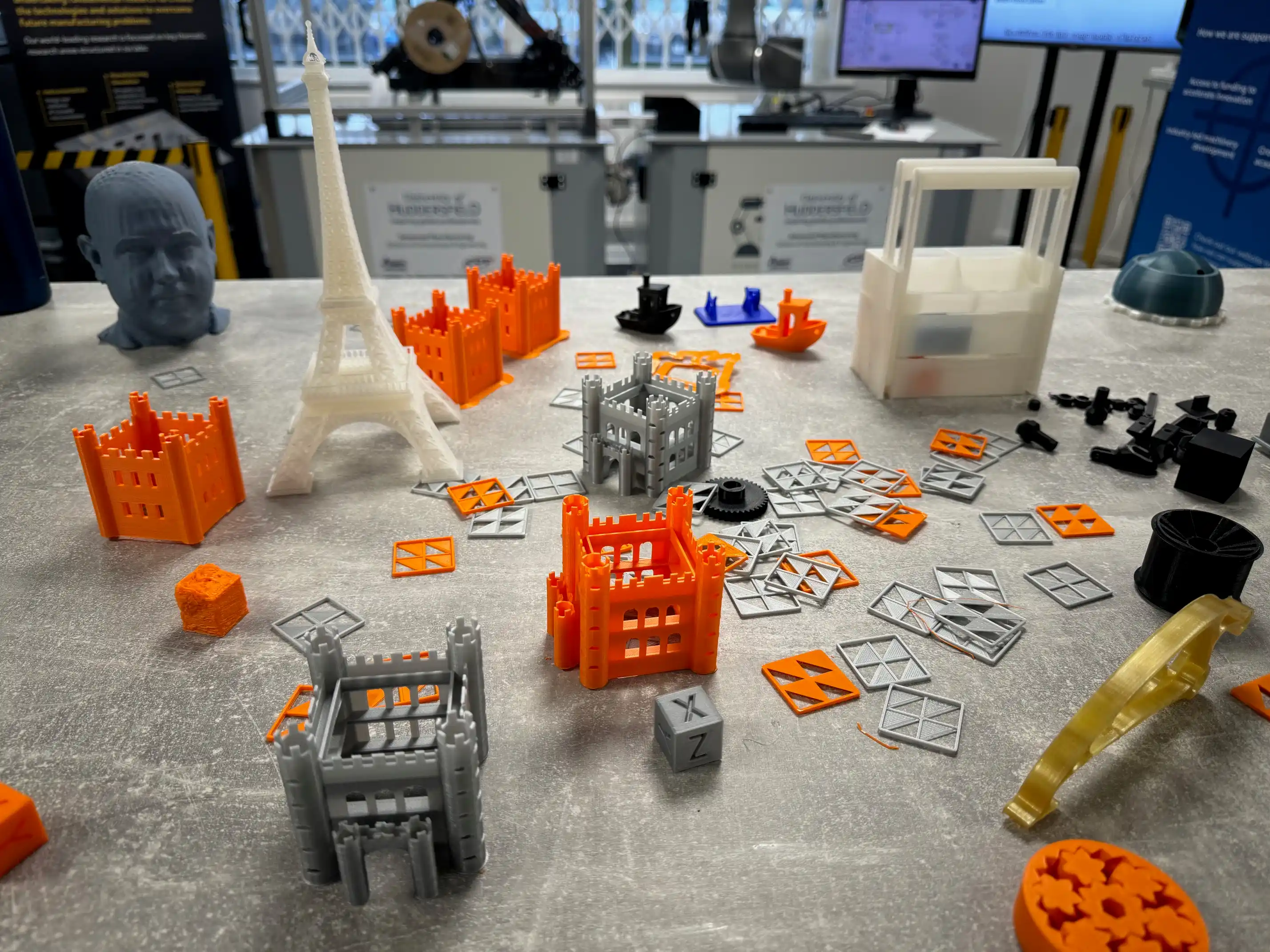

The Enginuity team kicked off its tour with Tabby Hanlon-Scott, Sector Engagement Lead, visiting West Yorkshire Manufacturing Services. This event gathered schools from across the region, introducing students to over 25 manufacturers and training providers. The celebration also offered interactive activities, displays, and discussions about opportunities within the sector.

We also had the opportunity to meet other interesting companies visiting West Yorkshire Manufacturing Services. They included Broadbent, who has implemented progressive policies to increase diversity, particularly for women in the workforce. A key driver for these changes was a female welding apprentice, prompting Broadbent to revamp its facilities, offer flexible working options, and develop supportive maternity policies. Another unique conversation was with Facultatieve Technologies, a company that designs cremation equipment. Their demonstration provided students with a thought-provoking glimpse into the vast range of careers in engineering, emphasising how engineering shapes all aspects of life – and death.

The University of Huddersfield also offered insight on increasing female participation in manufacturing, particularly in bio-chemical engineering. They shared how STEM outreach often involves an element of competition over teamwork and collaboration, a factor that could deter young women from pursuing careers in the sector.

A&M EDM

Enginuity’s Solutions and Innovation Impact Manager, Laura Giddings, visited A&M EDM in Smethwick, a high-precision engineering company excelling in automotive, aerospace, and Formula One manufacturing. The company employs 85 people, including eight apprentices. The visit highlighted the company’s focus on skill development through its hands-on apprenticeship program, allowing young talent to contribute to cutting-edge projects. One of their standout projects involves producing UAV engines for firefighting missions, demonstrating real-world impact.

The dedication of A&M’s apprentices is impressive, with one apprentice, Finlay, being a finalist for the prestigious Engineering Rising Star category at the Make UK Manufacturing Awards. The company's approach to fostering apprenticeships and engaging with local educational institutions highlights its commitment to the future of UK manufacturing.

Another particularly notable project involves the creation of a reaction engine heat exchanger part, valued at over £100,000 – a feat of precision manufacturing where the apprentices played an integral role.

Autins Group Plc

Enginuity’s Sector Engagement Lead, Mandeep Sandhu, visited Autins Group Plc in Tamworth, a company specialising in acoustic and thermal insulation solutions for the automotive industry. As part of the visit, Enginuity presented the Automotive Upskilling and Reskilling platform, highlighting how it can support the automotive supply chain. The visit provided insight into the entire production process, from fibres to finished products, underscoring the importance of thermal management and the diverse industries involved in the automotive supply chain.

UK Battery Industrialisation Centre

Mandeep also visited the UK Battery Industrialisation Centre (UKBIC) in Coventry, which provided a glimpse into the future of green technology. As an innovative facility for battery development, UKBIC bridges the gap between prototype and mass production. Enginuity’s visit coincided with the Ansys Battery Forum, a gathering of technologists, manufacturers, and academics. The forum explored the use of Ansys software to push boundaries with the predictive power of simulation, used for sustainable transportation, advanced semiconductors, satellite systems, and life-saving medical devices. The visit reaffirmed the importance of innovation in driving sustainable industrial practices.

Enginuity's commitment to the future of manufacturing

Throughout National Manufacturing Day, Enginuity’s visits showed the critical role manufacturers play in developing new talent, driving innovation, and tackling challenges like sustainability and diversity. By working alongside industry leaders, apprentices, and educators, Enginuity continues to champion the engineering sector and its pivotal role in shaping the future of UK manufacturing.

Thank you to West Yorkshire Manufacturing Services, A&M EDM, Austins Group PLC, and the UK Battery Industrialisation Centre for showing us around. We look forward to collaborating with you on future projects.

More news